Cress

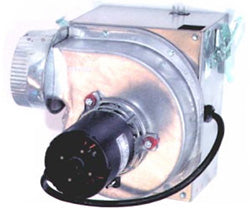

Cress Kiln Clean-Air Vent System

Cress Kiln Clean-Air Vent System

Couldn't load pickup availability

This system exhausts kiln fumes separately from the top, middle, and bottom of the kiln to prevent cross contamination of colors so they look their very best. It also keeps fumes out of your kiln room by venting them outside.

The exhaust fan automatically waits until the kiln turns on, then goes off when the firing is complete. When cooling, the fan turns back on at 1000ºF automatically and off at 140ºF for safe cooling to protect your pieces. This gives you the strongest properly annealed ware in the fastest possible time. Standard metal 4” dryer ducting is all that is required for the exhaust.

Venting Requirements:

Four inch metal dryer-type vent ducting is required to exhaust air to the outside.

Exhaust:

Air temperature of the exhausted air is approximately 20°F higher than the ambient room temperature.

Electrical Requirements:

The CRESS Vent System fan is supplied power through the control panel. The motor uses 220v power and draws .53 amps when operating.

Specifications:

Shipping weight is 15 pounds. Total airflow is 80 CFM. Maximum ducting distance: 70ft. Maximum number of bends is 4 sweeping bends. Motor: FASCO Industries, Inc., RPM 3000. CAS listing LR36496.

Use:

The vent system will come on at the beginning of a firing. Once the kiln has reached temperature the vent will turn off, then it will come back on at 1000° F to provide a slightly faster cooling rate. Then it will turn off when the kiln reaches 140°F. Now it is safe to unload your kiln and it is ready to fired again.

Agency Approvals:

The CRESS Vent System when used with a listed CRESS kiln is CSA listed and has been tested by CSA to the UL Standard 499. CSA is a nationally recognized testing laboratory.

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions