Peter Pugger

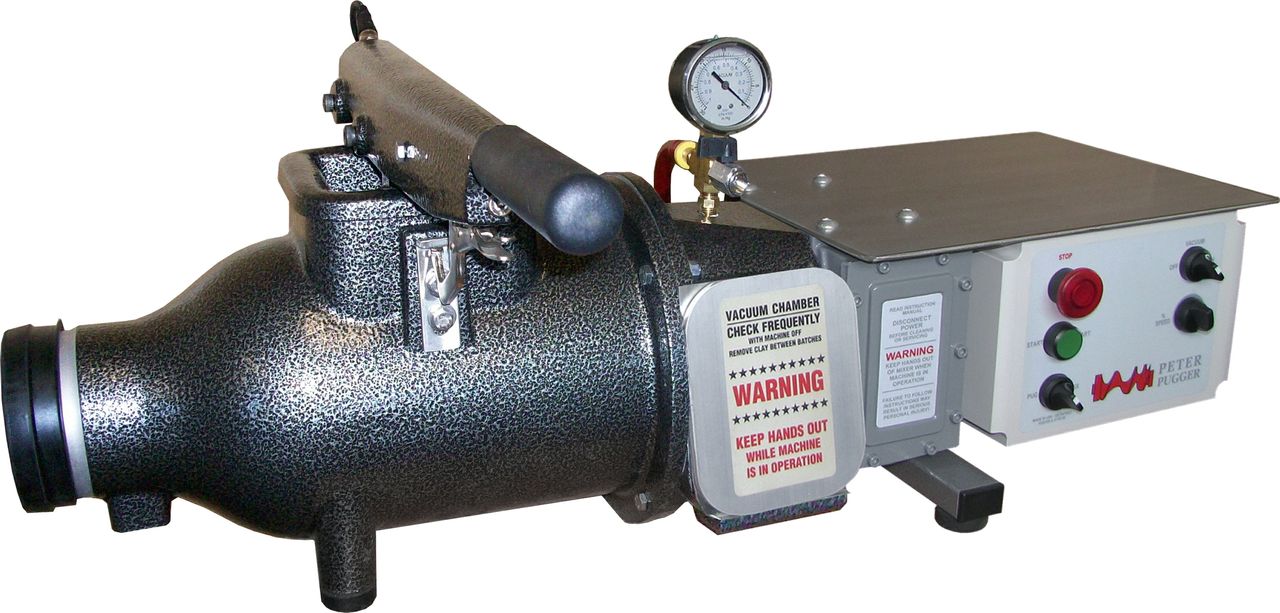

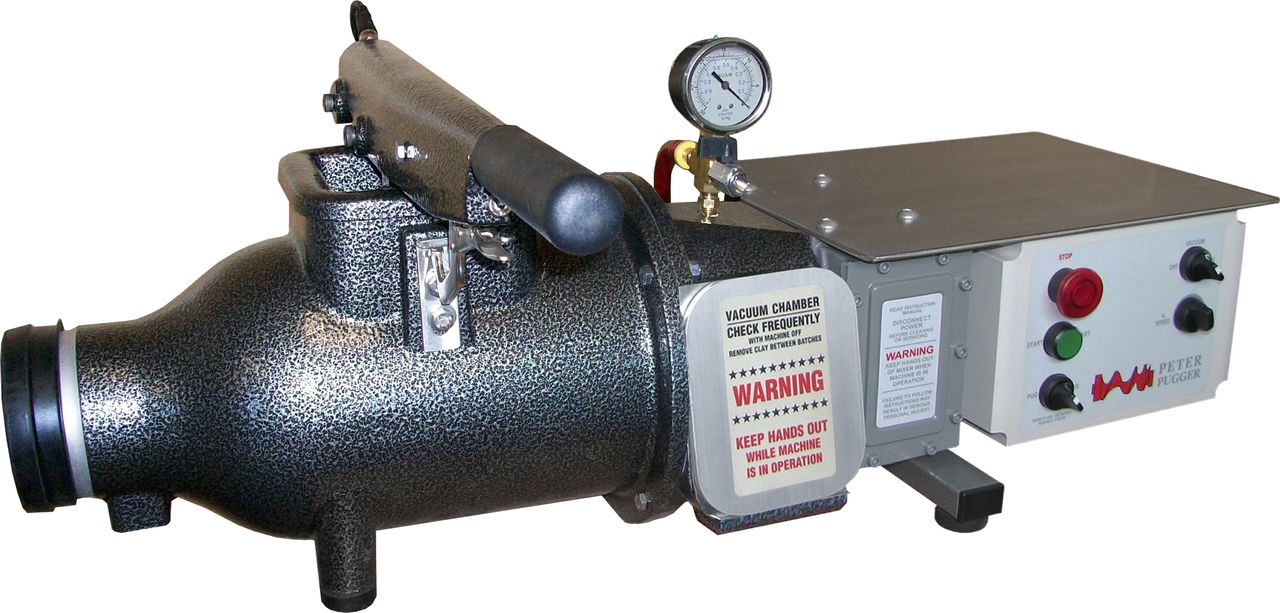

Peter Pugger VPM-9SS Vacuum Power Wedger (Stainless Steel)

Peter Pugger VPM-9SS Vacuum Power Wedger (Stainless Steel)

Couldn't load pickup availability

**Peter Puggers corrosion resistant model VPM-9SS is for potters using porcelain clay bodies with high alkalinity. The standard pugger has an aluminum body. Under stable pH conditions (4.5 -8.5), aluminum has the ability to form an oxide layer that allows it to be naturally highly resistant to corrosion. However, when the pH level rises above stable pH conditions, the oxide layer is unable to renew itself fast enough, causing corrosion or “pitting” of the aluminum. The VPM-9SS is made with a stainless steel body to mitigate the corrosion issue.

When the clay is adequately mixed, it can be de-aired with vacuum and pugged out in the form of logs ready for use.

+ Shaft, augers and paddles of stainless steel, along with aluminum mixing/pugging chamber, ensures rust-free clay processing.

+ Large Hopper: The oversized hopper door allows for easy loading of up to 25 lbs. of clay per batch.

Batch Mixing Capability: Full batch mixing and blending capability allows for moisture adjustment before pugging.

+ Switch to PUG after a batch is completely mixed, and the Power Wedger unloads itself in the form of 3" diameter deaired logs.

+ Each batch can be de-aired by starting the vacuum pump when the load is mixed. Air is removed during the last stage of mixing, leaving an air-free product when pugged out. Our patented vacuum design allows us to deair the clay without the use of cumbersome vacuum screens! Vacuum is provided by a 1/16 HP double-headed rocking piston type diaphragm pump. These new technology pumps are the simplest and quietest vacuum source available. They are maintenance-free and long lasting. The VPM-9 Power Wedger does not require a large vacuum pump because the clay is continuously exposed to vacuum in the sealed mixing chamber. Once the clay chamber is evacuated, the vacuum pump can be turned off.

+ Leaving moist clay in the Power Wedger is not a problem. All the openings are sealed so clay will stay moist indefinitely.

+ Real-time monitoring of clay consistency can be accomplished while mixing. Similar to an automatic transmission, the Pugger-Mixer can automatically speed up or slow down based on the hardness of the clay being processed. The operator can also control the speed by controlling the variable speed knob.

+ This allows the operator the ability to speed up or slow down the pugmill. This is especially useful when extruding through dies. Because of the back pressure generated by a large amount of clay being forced through a small orifice, the speed control allows the operator to slow the pugging as required. In turn, perfect deaired configurations are easily extruded through the Pugger-Mixer. There are additional advantages if you are a "single potter studio". The ability to slow the pugging allows for time to place pugged clay into containers or bags.

+ The stainless steel work surface creates a durable work surface for convenience of the operator while loading. The work surface is 12" x 14".

+ It is not necessary to continuously hand-feed the Power Wedger as with standard pugmills. Load a full batch, close the lid and turn it on - this eliminates exposure to moving paddles. The Power Wedger shuts off automatically when the lid is opened. All machines are equipped with a thermal overload for protection against overheating.

+ Cleaning With the removal of four bolts, the entire mixing/pugging chamber can be removed so it can be conveniently washed off. The paddles are then easily accessed for cleaning. Cleaning is necessary only to avoid cross contamination. Since the machines are completely sealed, moist clay can be stored indefinitely without drying out. Cleaning is necessary only to avoid cross-contamination. Since the machine is completely sealed, it can be left for long periods of time without the clay drying out.

Variable speed comes standard on the VPM-7, VPM-9 and VPM-20.

Materials

Materials

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

Care Instructions

Care Instructions